PVC Artificial Marble Sheet&Profile ProductionPVC Artificial Marble Profile Production line

Introduction

This kind of PVC imitation marble stoneplastic production lineis mainly usd to produce the skirting panel profile for ceiling, wall panel, background wall, window frame, door frame, skirting board, elevator door frame, etc., special for public and private decoration, such as villa, house, hotel, shopping mall, and so on.

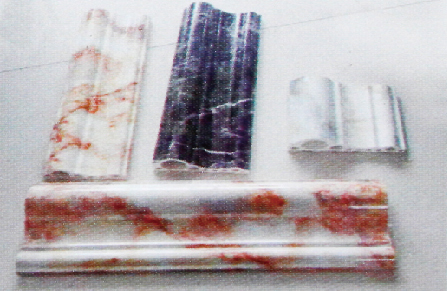

New product! 100% replacement of the real marble

Features of the moulding profiles:

1. Green environmental protection, also recyclable.

2. PVC super wear-resistant floor surface has a layer of special by high-tech processing transparent wear-resistant layer, withwear resistance strong, so PVC floor more and more popular in the hospital,in school, office buildings, shopping malls,supermarkets, transportation and other places.

3. Safety, insulation, flame retardant, corrosion resistance, acid and alkali resistance, 5% acetic acid. 5% hydrochloric acid, no abnormal surface. Leave the flamefor five seconds and can self extinguish.

4. Novel color, a variety of colors available for selection, brilliant color,natural and vivid color, any spell group shape, highlight the individuality color.

5. Installation convenience,convenient construction sawing, planing, nail, glue free paint.

6. Long service life can reach more than 20 years.

Usage:

1. Used as background wall frame for the TV, sofa, etc.;

2. Used as the door frame for great decorative effect, etc.;

3. Used as the decorative ceiling corner, etc.;

4. Used for the hotel, restaurant, living room and many other places;

5. Door frame moulding, edge banding, press line, skirting, borders, Vertex angle line, pull through plate, ect.

Models:

| Model | Main Motor Power(kw) |

Vacuum Pump Power(kw) |

Haul-off Speed (r/min) |

Total Power(kw) |

Extrusion (kg/h) |

Profile TransferMachine |

Area Requirement(m) |

| 45/90 | 18.5 | 4 | 0.5-12 | 54 | 120 | 5-8 | 16*2.5 |

| 51/104 | 30 | 4 | 0.5-10 | 71 | 150 | 5-8 | 17*2.5 |

| 65/132 | 37 | 5 | 0.5-6 | 83 | 250 | 5-8 | 19*3.0 |

| PVCrawmaterialsMixingsystem | |

| 1.SpiralLoaderorVacuumautoLoader | 1set |

| 2.HighspeedHeatingCoolingMixerunit | 1set |

| PVCMouldingProfilesExtrusionLine | |

| 1.SpringLoader | 1set |

| 2.SJZ65/132ConicaldoublescrewExtruder | 1set |

| 3.Mold/DieheadSet | 1set |

| 4.VacuumcalibrationTable | 1set |

| 5.ThermalPrinter | Multiplesets |

| 6.Hauloffunit | 1set |

| 7.Cuttingunit | 1set |

| 8.Stacker | 1set |

| ProfilesRecyclingmachines | |

| 1.Sheet/PlateCrusher/Grinder | 1set |

| 2.PVCPulverizer/Miller | 1set |

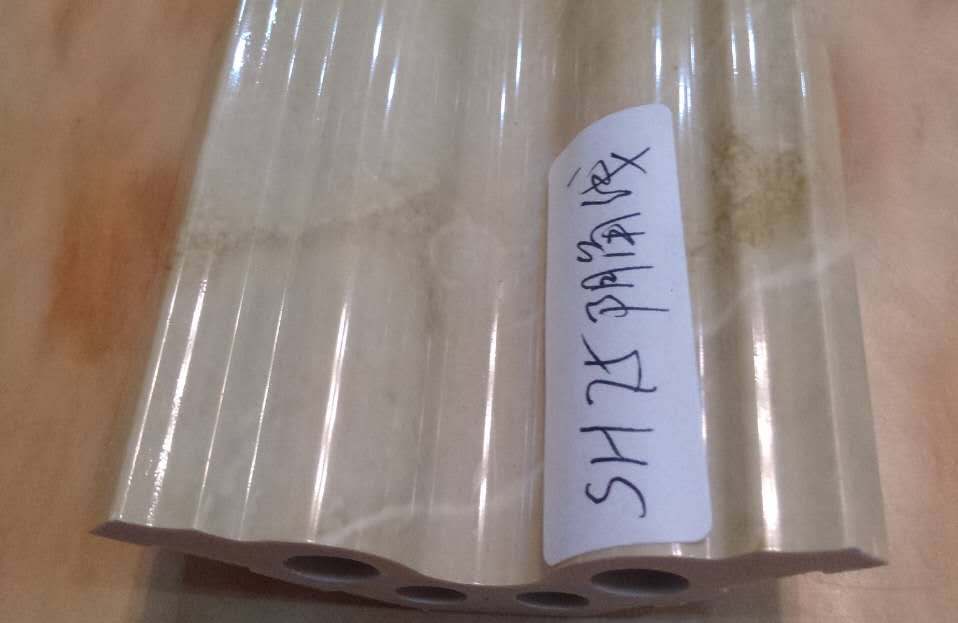

Reference Photos

Leave a Message

Your email address will not be published. Required fields are marked