Roofing Tile Production LinePlastic Hollow Roofing Tile Making Machine

Introduction

1) plastic hollow corrugated tile making machine,double wall corrugated roof machine manufacturer

consists of extruders, extrusion mould,

calibration system, haul-off machine, cutter and stacker.

2)The extrusion mould adopts the latest co-extrusion technology with very precise design

with multi-cavities.

3)The shaping mould includes the vacuum calibrating system and special design of cooling

runner with excellent cooling effect.

4)The surface UV-layer is co-extruded with ASA/PMMA bright color, which is not easy to fade.

Specifications:

|

Main extruder |

SJZS-80+SJ-50 |

SJZS-92+SJ-65 |

|

Width of finished product |

830 mm |

1000 mm |

|

Thickness of finished product |

12mm |

14mm |

|

Drive motor |

55kw+15kw |

110kw+18.5kw |

|

max output |

300kg/h+50 kg/h |

600 kg/h+80kg/h |

Applications:

The plastic hollow corrugated tile making machine,double wall corrugated roof machine manufacturer is mainly used in the production of plastic twin wall hollow roofing sheet , which compared with traditional plastic roofing sheet, this twinwall hollow roofing sheet is better for heat and soundresistance. It is suitable for tropical weather with advantage of anti-corrosion, rustproof, strong durability, and beautiful appearance, easy and fast installation. Because of the stronger rigidity, the twinwall hollow roofing sheet is widely used in the factories (including chemical and treatment plant), sports stadium, schools, agriculture industry, marine, warehouse and commercial buildings.

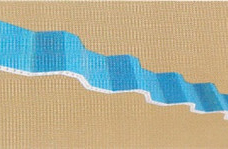

Reference Photos

Leave a Message

Your email address will not be published. Required fields are marked